As research in engineering leads to advancements in design, technology and methods, scientists strive to strengthen materials. University researchers recently analyzed the benefits of gradient nanotwin boundaries — tiny linear divisions with identical structures on either side — in certain metals, such as copper.

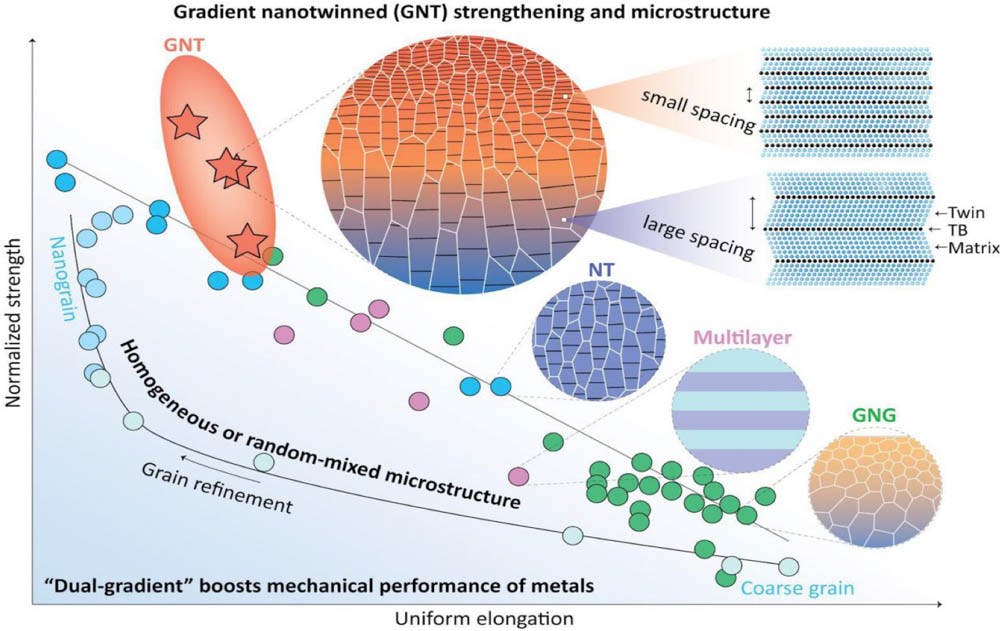

The main areas studied were the overall strength of the copper and its ability to stretch. As a metal becomes stronger, it cannot be stretched as much. This “trade-off has been a long-standing dilemma in materials science,” wrote Zhiwei Ma, postdoctoral research associate, in an email to The Herald. “We were looking to find a way of enhancing the strength of steel at no ductility trade-off.” In the metals with gradient nanotwin boundaries, however, this trade-off was rarely seen, Ma added.

“It becomes essential to understand how the micro, nanostructure controls the property of metals,” said Huajian Gao, professor of engineering and co-lead researcher of the study.

The symmetry of nanotwin boundaries enhances the metal’s properties and further impedes dislocation. “They are one of the most perfect grain boundaries,” Gao said. These nanotwin boundaries reinforce the metal and increase its overall strength, he added.

Nanotwin boundaries are one form of grain boundaries, which are divisions within the nanostructure of a metal that reinforce it, Gao said. These boundaries only form in certain metals, such as copper and gold, and reinforce natural atomic defects that slowly pass through the metal, he added. The slowing of this process without stopping it entirely is crucial; if these defects are impeded altogether, the metal becomes brittle and weak, but if the defects pass through with ease, the metal will wear down.

Researchers strive for this ideal zone to optimize metals. “Metal is used as a structural material everywhere; it is one of the most important materials in engineering,” Gao said.

In addition to the introduction of twin boundaries, the use of a graded texture from coarse to dense, or vice versa, lessens the weakness of a uniform nanostructure. This creates a more diverse inner working of the metal, further strengthening it, Ma said. “We’re trying to mimic nature,” Gao said, alluding to the wide variety of organic materials, such as bone and wood.

The team hopes to see similar applications with the use of high entropy alloys, which comprise equal parts of five or more metals, as opposed to traditional alloys with a majority composition of one metal, Ma said. This equal distribution allows for easier manipulation of the alloy’s properties to match a given metal, Gao added. Specifically, steel alloys can benefit from these nanostructures to enhance performance in axles in machines and transmissions systems in a number of industries, Ma said.

While it may take a few years to understand the full scope of the ways nanotwins can affect metals, Gao is hopeful to see their use in a wide range of products. “We still have to understand them first. We have to develop road maps to figure out how to go from here to there,” Gao said. As knowledge of the field increases, these alloys and material science methods could be used in handheld technology, aerospace engineering and car manufacturing, Gao said. “Maybe in the next decade or two we’ll see a lot of breakthroughs in material technology, … (but) now we’re just trying to understand from a basic science point of view how it all works,” he added.